Few experiences can match the thrill of riding a roller coaster, from the anticipation as the car climbs steep inclines to the adrenaline rush of sudden drops and high-speed twists. But behind every scream-inducing loop and carefully calculated turn lies a complex process of engineering, design, and construction. Building a roller coaster involves a meticulous blend of artistry and science, ensuring not only optimal excitement but also the highest standards of safety.

It all begins with a concept. Theme parks identify the type of experience they want guests to have—whether it’s a high-speed steel coaster loaded with inversions or a classic wooden structure with nostalgic appeal. Once the style and theme are selected, the real work begins.

1. Design and Planning

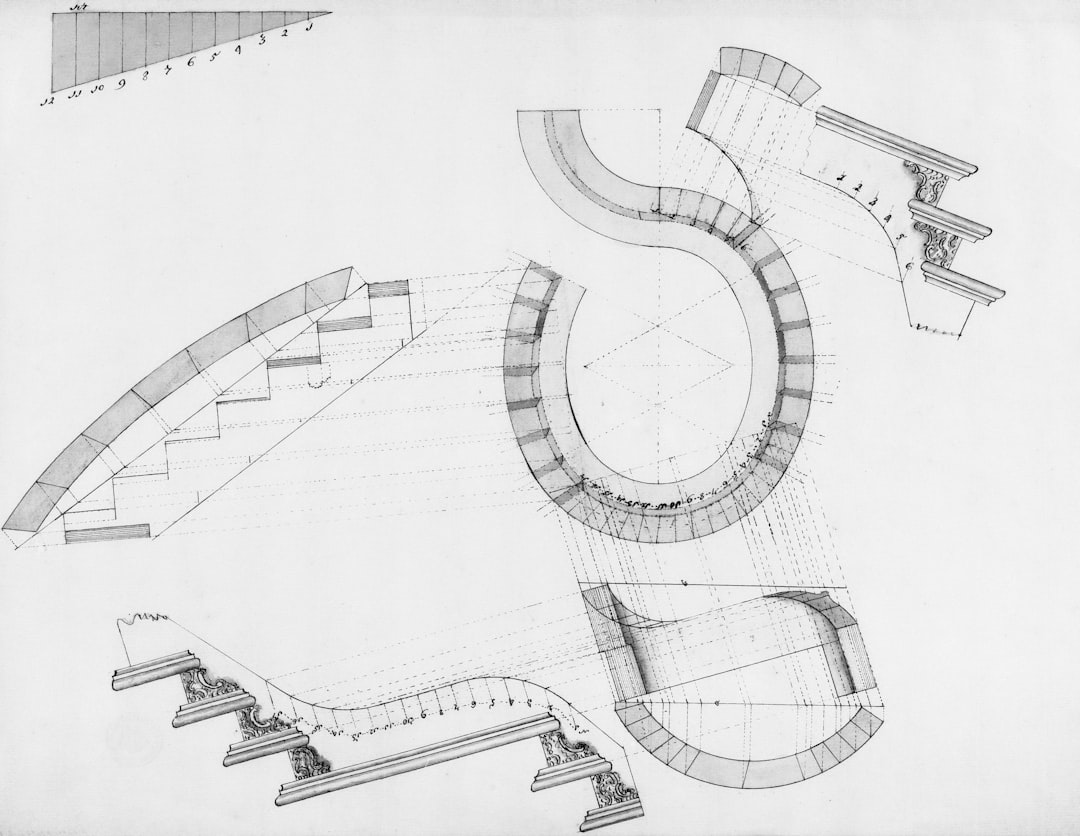

The first stage in roller coaster construction is the design phase. Engineers and designers use specialized software such as AutoCAD and NoLimits Coaster to craft detailed virtual models. This stage allows creators to simulate ride physics, test safety measures, and experiment with variants of the ride layout.

Designers consider many variables:

- Speed and height for thrill level

- G-force calculations to ensure it’s safe and enjoyable

- Local climate and terrain

- Theming and aesthetics

Regulations and building codes must also be reviewed at this stage, and permits are secured before proceeding to the next point.

2. Manufacturing Components

Once the specifications are locked in, manufacturers begin creating the components of the ride. For steel coasters, this includes precision-fabricated steel track pieces, support beams, and mechanical hardware. For wooden coasters, high-quality treated lumber is pre-cut and reinforced for durability.

The roller coaster cars themselves are engineered for speed, safety, and passenger comfort. Each part undergoes stringent quality control and is shipped to the construction site when ready.

3. Site Preparation and Foundation Work

Before any structure can rise, crews prepare the land. This might involve leveling the ground, managing drainage, or reinforcing the soil to handle the ride’s weight and dynamic forces. Columns, footings, and anchor plates are embedded deep into the ground to give the coaster a firm base.

4. Track Assembly and Construction

Construction teams then begin the formidable task of assembling the track. Cranes lift heavy steel segments into place, where they are bolted and welded securely. Each segment is carefully aligned to match the digital model; even minor misalignments can compromise the ride’s integrity.

Support structures are erected alongside the track, ranging from lattice frames for high-speed sections to inclined towers for initial lift hills. Many modern coasters use magnetic or chain lift systems to begin the ride’s arcing journey skyward.

5. Systems and Electronics

Modern roller coasters are sophisticated machines equipped with advanced electronics. Sensors track each car’s position, while programmable logic controllers (PLCs) manage braking, acceleration, and safety interlocks. These systems work in sync to ensure precise timing and to prevent collisions.

Emergency stop mechanisms, cameras, and other fail-safe features are installed during this phase, and everything is rigorously tested before ride commissioning.

6. Testing and Safety Checks

Long before welcoming the public, rollbacks and test runs are conducted repeatedly. Weights often represent passengers while engineers analyze real-time data regarding G-force loads, vibration levels, and braking distance.

Once the authorities inspect and certify the installation, ride operators are trained, and the coaster is ready for its debut.

FAQ

- Q: How long does it take to build a roller coaster?

A: It usually takes 12 to 24 months, including design, manufacturing, and construction. - Q: Are roller coasters safe?

A: Yes. They undergo extensive testing and must meet strict industry and governmental safety regulations. - Q: How much does a roller coaster cost to build?

A: Costs can vary widely, ranging from $1 million for a small ride to over $50 million for large, custom-designed coasters. - Q: What materials are used in roller coasters?

A: Common materials include steel, wood, aluminum, and composite plastics. - Q: Do designers ride their own coasters?

A: Often, yes! Many engineers participate in initial test rides to experience the result firsthand.

Building a roller coaster is a remarkable undertaking. It combines engineering innovation, precision construction, and a healthy dose of imagination to deliver awe-inspiring rides that leave lasting memories—and plenty of screams—in their wake.